09

11 2020

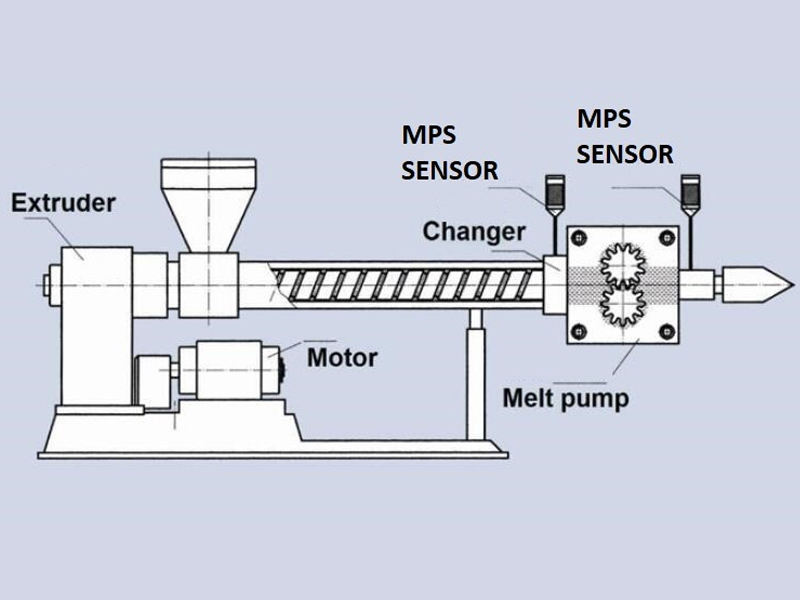

Melt Pressure Sensor Recommendations

The recommendations below are intended as a guide for selecting, installing and maintaining

melt pressure sensor transducers in systems experiencing severe pressure transients.

• Melt When replacing a transducer that has already been damaged by pressure spikes, use a transducer with the highest practical pressure range. For example, replace the damaged 2500 psi transducer with the 3000 or 5000 psi model.

• Bleed air from hydraulic system before operating.

• Use the absolute minimum pipe length between the Melt Pressure Sensor Transducer and the pressure point point. Mount the transducer as close as possible to the piston inlet port when measuring the ram inlet pressure.

• Avoid installing the Melt Pressure Sensor Transducer at the end of long, straight pipelines.

• The most damaging spikes are caused by the rapid change in system flow rate. If the fast acting solenoid valves stop flow, the pressure increase can be too high. If possible, slow down valve closing speeds to reduce or even eliminate shock shock. This applies to all fast acting flow controls.

• Install an appropriately sized pressure damper on or near the transducer to protect against pressure spikes