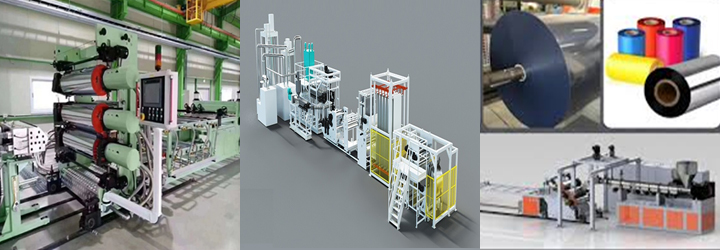

Sheet Extruder Processes

Polymer Sheet; Thicknesses from 0.5 mm to 12.5 mm. Used to obtain flat products and semi-finished materials for thermoforming. All thermoplastics, polyethylene, mostly low density PE Polypropylene (PP) Polyvinylchloride (PVC) Cellophane Production Methods Sheet and Film Production Methods Most commonly used mass production methods: Slit Die Extrusion Slit-Die Blown Film Extrusion Rolling Calendering ” Slit Die Extrusion Sheet is produced using the extrusion method with the aid of a die containing a thin slit The slit can be up to 3 m wide and as narrow as 0.4 mm. The polymer melt undergoes very large deformations during flow and therefore it is difficult to obtain a constant product thickness across the width. Since the edges are thicker, the edges usually need to be trimmed.

General Parts:

The raw material hopper consists of extruder driven motor, gear reducer box, screw and barrel, heater, cooling tank, roller, mold, hopper and control cabinet.

Working Principle:

The working principle of the extruder is as follows: the product moves in the hot line. In this way, it reaches the required temperatures and mixtures to form a homogeneous melt. The pressure created then forces the melt through the extruder. It comes out in the form of a mold. The product cooled from the cooling unit is passed through rollers and stacked by cutting according to its dimensions.

What is a Melt Pressure Sensor?

Melt Pressure Sensor is an instrument used to measure the pressure and temperature of melted liquids (optional) in processes where plastic raw materials can reach high temperatures.

Why is a Melt Pressure Sensor Necessary?

Almost all extruders use at least one melt pressure transducer because it is desirable for melt pressure/temperature control to improve the quality of the extrusion process.

Safety

Equipment Protection

Higher Efficiency

Higher Product Quality

Melt Pressure Sensor Applications for Plate Extruder Processes;

Pre-Filter Melt Pressure Sensor / Melt Pressure Control Application

Post Filter Melt Pressure Sensor / Melt Pressure Control Application

Melt-Gear Pump Pre-Melt Pressure / Melt Pressure Control Sensor Application

Melt-Gear Pump Post Melt Pressure Sensor / Melt Pressure Control Application

Aim:

*Checking the melt pressure, flow stability,

* To ensure the formation of the necessary pressure for production,

*Monitoring for possible contamination that could clog the filter changer and cause pressure drop in the mold, and as a result to determine if clogged filters need to be replaced (therefore the pressure is measured before and after the screen changer)

*The gear pump is used to give a constant flow rate to the mold: the flow is adjusted based on the measured pressure value (the pressure value is used to give feedback to the driver for screw speed adjustment)

*Creating necessary prescriptions for production,

* Evaluation of plastic raw materials,

*Controlling Pressure,

*Preventing excessive pressure on the screw,

* Protecting screw wear,