22

11 2024

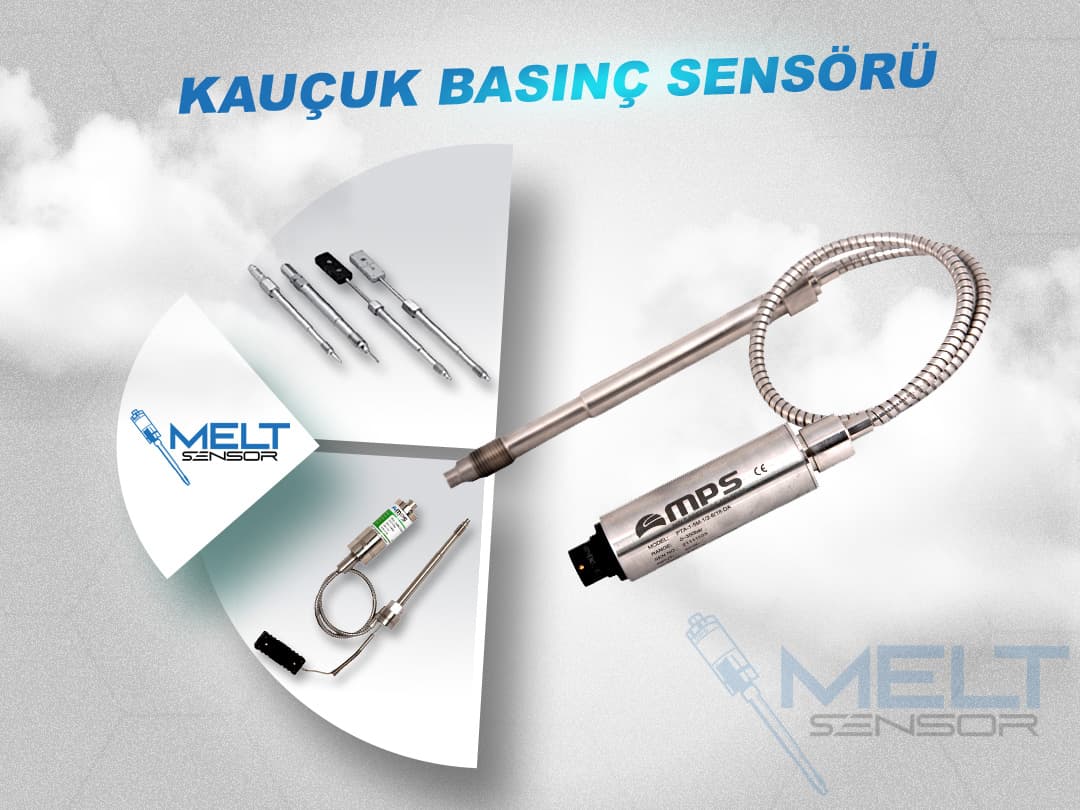

Rubber Pressure Sensor and Areas of Use

Rubber pressure sensors are devices that provide precise measurement, designed by taking advantage of the deformation properties of elastomeric materials. These sensors, which generally stand out with their flexible structures, have a wide range of applications from industry to consumer electronics due to their low cost and durability.

Working Principle

These sensors work on the principle that the rubber material undergoes mechanical deformation when exposed to pressure and converts this change into an electrical signal. The deformation is measured thanks to the piezoresistive or capacitive elements they contain and an output is produced depending on the pressure level.

Advantages

Flexibility and Lightness: Thin, flexible structures provide portability.

Durability: Resistant to harsh environments.

Cost Efficiency: Suitable for mass production and low cost.

Areas of Use

Healthcare Sector: Used in blood pressure monitors and prosthetics.

Automotive: In tire pressure monitoring systems.

Consumer Products: Providing touch sensitivity in smartphones and wearable devices.

Robotics: In human-machine interactions.

Developing material technologies enable rubber pressure sensors to become more sensitive, lightweight and suitable for integrated systems.