03

12 2024

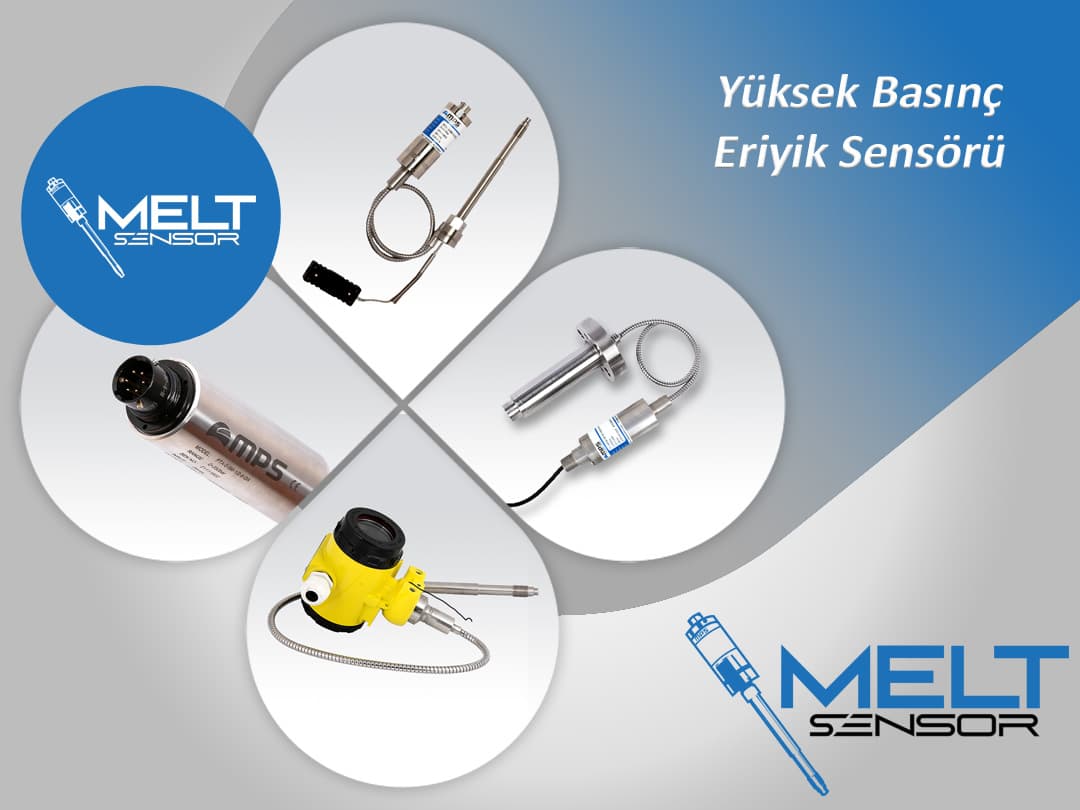

High Pressure Melt Sensor

A high-pressure melt sensor is a sensitive device used to measure the pressure of molten materials in industrial processes. It plays a critical role especially during the processing of materials such as polymers, plastics and rubber. These sensors are used to ensure process safety, improve product quality and optimize energy efficiency.

Working Principle of High-Pressure Melt Sensor

High-pressure melt sensors usually have a diaphragm or sensing element that comes into contact with the molten materials. This diaphragm detects pressure changes and uses piezoelectric or strain gauge technology to convert mechanical motion into an electrical signal. This signal is transmitted to a control system to perform pressure measurement.

Features

High Temperature Resistance: It can operate at temperatures of 400°C and above.

Precise Measurement Capacity: It can detect changes at the micron level.

Chemical Resistance: It is made of materials resistant to corrosive and abrasive substances.

Long-Life Performance: It is designed to operate for long periods under high pressure.

Areas of Use

Plastic Injection and Extrusion

High pressure melt sensors are used in plastic injection machines and extrusion lines. In these processes:

The pressure of the polymer melt is controlled to ensure a smooth flow.

Optimal pressure levels are monitored during mold filling.

Product surface quality and mechanical properties are improved.

Petrochemical and Polymer Industry

Pressure sensors are critical for monitoring polymer production processes in petrochemical plants. During polymerization:

The pressure inside the reactor is balanced.

Pressure data is optimized to increase product purity and homogeneity.

Food Industry

High pressure melt sensors are also used in processes such as food extrusion. In particular:

Snack production,

Pressure control is provided in high temperature confectionery and chocolate processing processes.

Medical Applications

Sensors help control processes that require high precision during the use of melt materials in the production of medical devices and equipment.

Research and Development Laboratories

High pressure melt sensors are frequently preferred in laboratory environments for the development of new materials and process optimization.

Advantages

Process Optimization: Provides precise control over process variables.

Energy Efficiency: Prevents unnecessary energy consumption.

Increased Safety: Prevents possible accidents with an early warning mechanism in cases of excessive pressure.

Product Quality: Increases stability in production and reduces the rate of defective products.

High pressure melt sensors are an indispensable tool for the safety and efficiency of industrial production processes. Equipped with advanced technology, these sensors increase quality and performance in different areas of the industry by making accurate and reliable measurements. With developing technology, these sensors are expected to become even more sensitive, durable and user-friendly.