25

09 2025

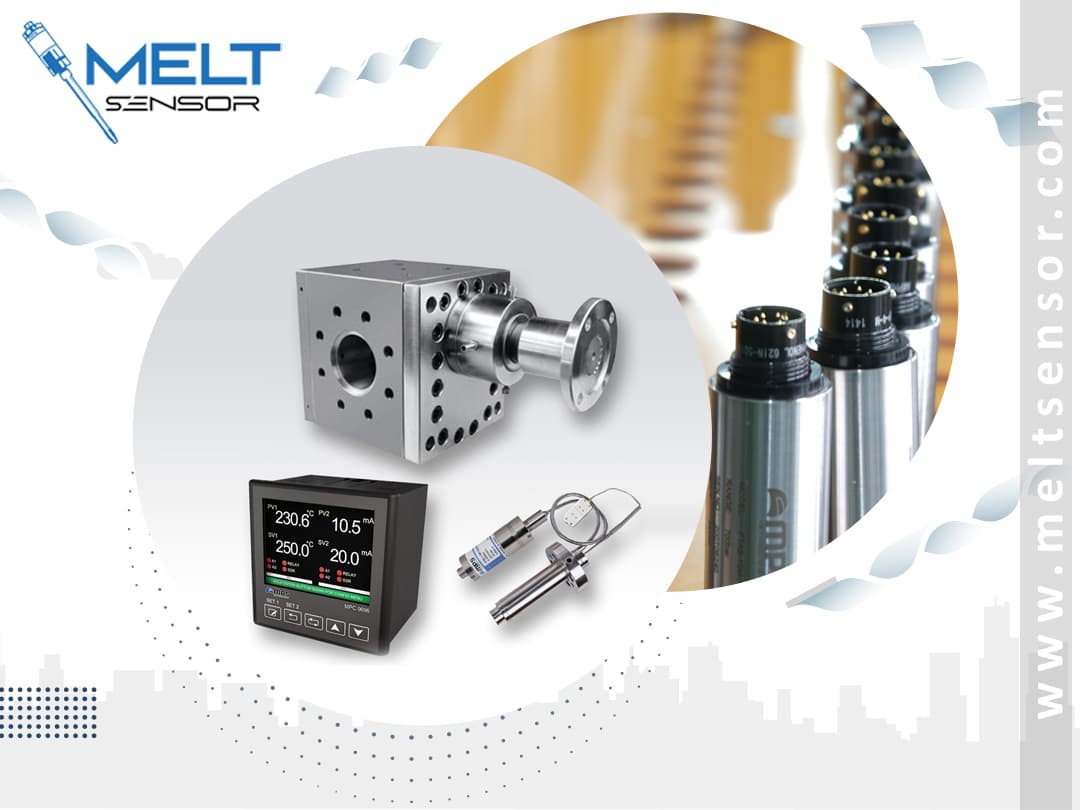

Recommended Set Configuration from Melt Sensor

Recommended Set Configuration from meltsensor.com

Pressure Sensor: 0–250 bar, 4–20 mA output, integrated type J thermocouple

PID Controller: Universal input, 2 alarm relays, 1 analog output (4–20 mA)

Accessories: 1/2-20 UNF mounting adapter, heat shield, 5 m high-temperature cable

Options:

Second analog output for cascade control

Upstream system integration with digital communication (Modbus/RTU)

Ramp-soak profiles and recipe management

Request a quote/drawing: simply share process pressure range, line speed, material (MFI/MFR), die type, and existing drive information.

Closed-loop PID control of gear pump inlet pressure provides measurable quality improvements and cost reductions in extrusion processes. With the right sensor selection, appropriate PID settings, and safe alarm scenarios, your line will operate faster, more stable, more efficiently, and more predictably.

Let's optimize together. Share your line data (pressure range, material, target line speed), and we'll recommend a control set specific to your process.