16

07 2024

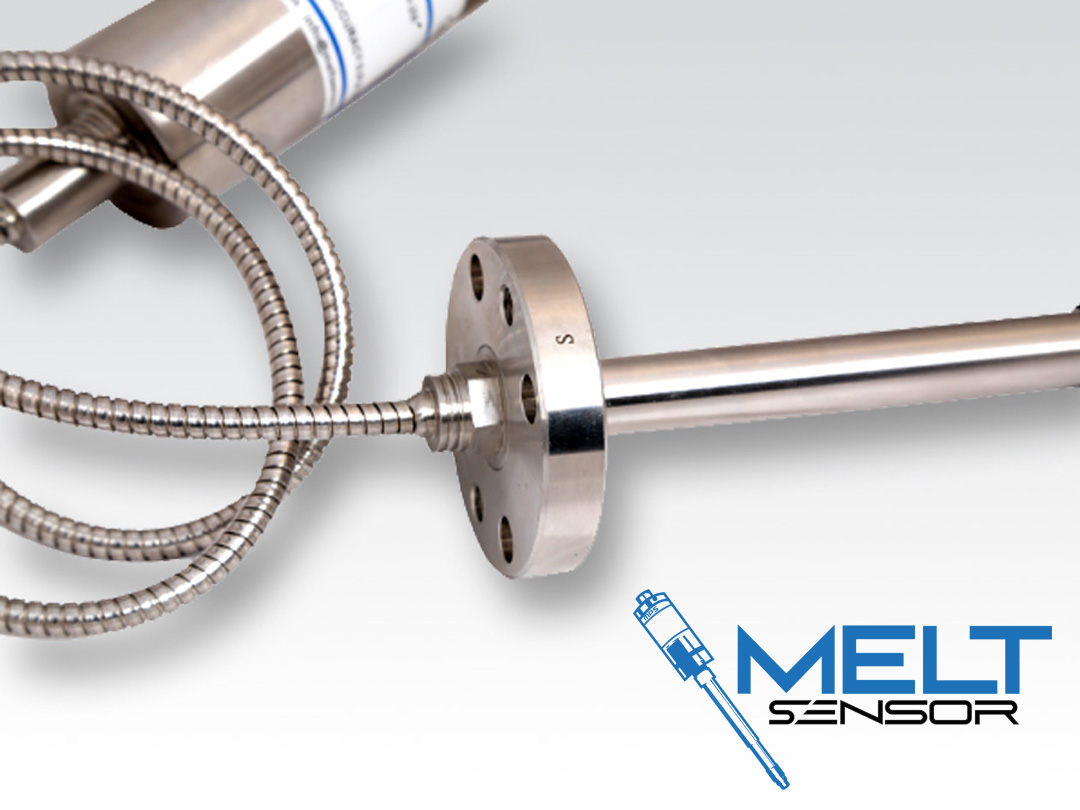

Melt Pressure Sensor Cables and Connectors

Melt pressure sensors generally use specific wiring and connectors to transmit electrical signals and make connections. These elements are used to connect the sensor with the control system or data acquisition systems. Here are some of the types of cable connections and connectors commonly used in melt pressure sensors:

Cable Ends:

Cable leads for simply connecting wires directly to or from the sensor.

Soldered Connectors:

Connectors used to connect cable ends to the sensor by soldering.

Screw Connectors:

Connectors used for connecting cable ends to the sensor by screwing. These types of connectors generally provide a more robust connection.

Concealer Connectors:

Sealing connectors used to protect the connection to the sensor against water or dust. These connectors are generally waterproof.

Magnetic Connectors:

Connectors that use magnetic force to facilitate connection to the sensor. These types of connectors can be easily connected and removed.

M12 or M8 Connectors:

Standard M12 or M8 connector types commonly used in industrial sensor applications. These connectors are generally preferred in industrial environments.

Cable Sleeve Connectors:

Cable sleeve connectors used to protect and strengthen cable ends. These connectors are useful to prevent cable damage.

Connector Boxes:

Connector boxes used to protect the connection with the sensor and increase resistance to external factors.

Cable connections and connectors are important for the reliable operation of the sensor and data transmission. The suitability of these connectors depends on the environment in which the sensor will be used, the electrical requirements and the application conditions. Installation manuals and technical documentation provided by the manufacturer can guide you in selecting the correct cable connections and connectors. As MPS, in addition to our own specially produced Melt Pressure Sensors, we also supply Gefran, Dynisco and Sand products at the most affordable prices.