03

10 2023

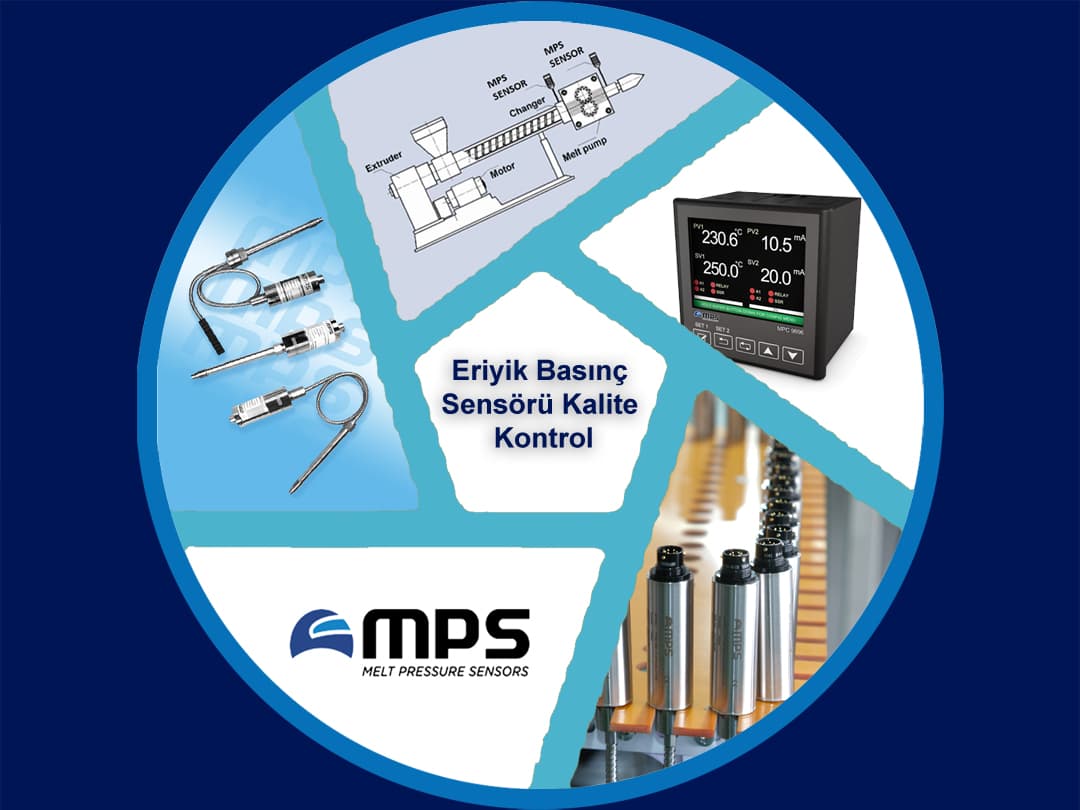

Melt Pressure Sensor Quality Control

Quality control is an extremely critical process in the production of precision industrial devices such as melt pressure sensors. Correct implementation of quality control is important to ensure the reliability, precision and durability of the sensors produced. Here are the basic steps of melt pressure sensor quality control:

Input Control: Input control is carried out on incoming materials and components before starting production. This includes verifying that materials and components meet certain quality standards and specifications. Quality input materials positively affect the quality of the final product.

Workmanship Control: During the production process, workmanship control is carried out at every stage. Workmanship control aims to detect errors in assembly lines, material handling operations, and operations such as soldering. This is especially important for manual assembly operations.

Functional Tests: The manufactured sensors are introduced into special testing equipment or test environments to test their functionality and accuracy. Tests are performed to evaluate the response and sensitivity of the sensor under pressure and temperature conditions. These tests help determine whether your sensor meets certain performance requirements.

Calibration: Every sensor needs to be calibrated. The calibration process adjusts the sensor's response to pressure and temperature within a specific range. An uncalibrated sensor cannot measure accurately.

Traceability and Documentation: Records of each sensor produced are kept and traceability is ensured. This means that each sensor is traceable and can be examined retrospectively if necessary. Additionally, it is important to document the manufacturing process and record the sensors' specifications.

Intensive Tests: Extra intensive tests may be required, especially for sensors to be used in critical industrial applications. These tests aim to determine how durable the sensor is under extreme conditions.

Sample Collection: Samples are taken from the sensors produced at regular intervals throughout the production process and subjected to detailed examination and testing. This is a way to ensure that the manufacturing process consistently produces quality products.

Reporting and Improvement: Data obtained from the quality control process is used to improve the production process and correct errors. Errors and problems are reported and fixed.

Melt pressure sensor quality control aims to ensure the reliability and performance of the product and is generally carried out in accordance with international quality standards. The quality control process must be applied continuously to ensure that each product has a consistent level of quality.