05

06 2023

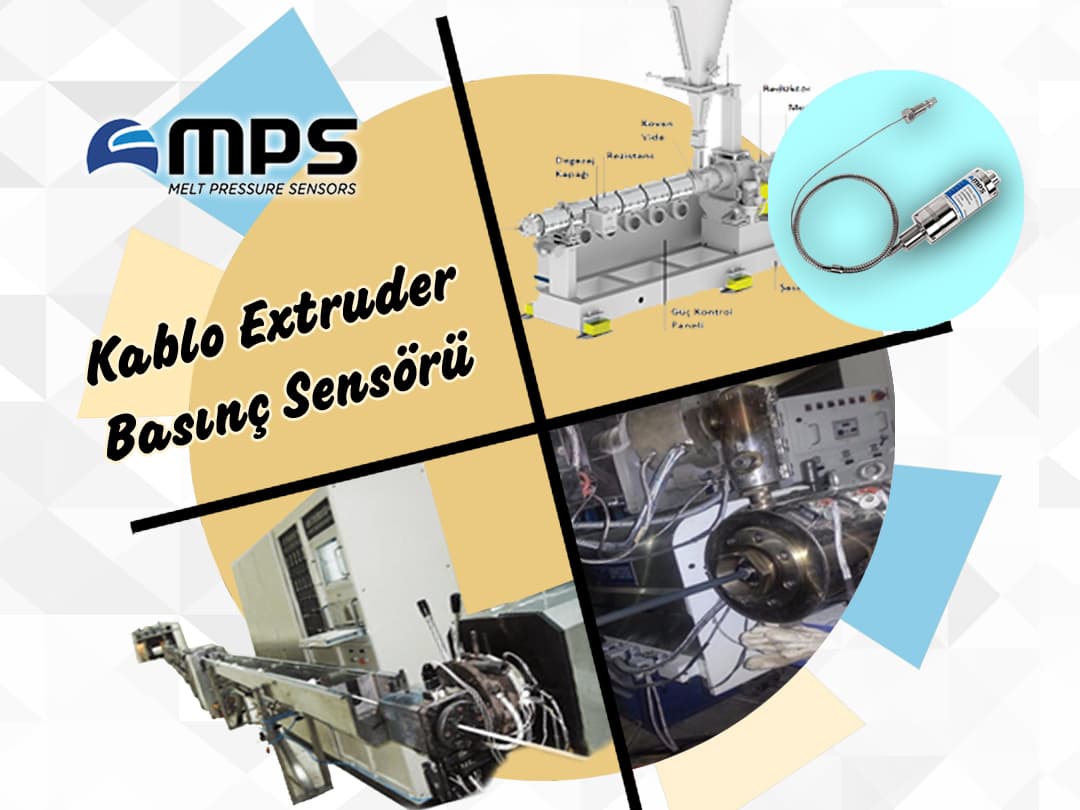

Cable Extruder Pressure Sensor

Cable extruder pressure sensors are sensors used to measure the pressure in extruder machines used in cable production. Cable extruders are machines that continuously extrude cable materials made of metal or plastic.

The operating structure of cable extruder pressure sensors generally includes the following components:

Sensor: The sensor acts as the pressure sensitive part that comes into contact with the cable material. The sensor usually has a diaphragm, piston, or similar structure. Pressure exerted on the cable material causes deformation of the sensor, and this deformation produces a physical or electrical property that changes depending on the pressure.

Converter: A converter is used to convert the physical or electrical signals produced by the sensor into a measurable format. This conversion usually takes the form of conversion to electrical signals. For example, if the pressure sensor has a resistance or capacitance based sensor, the converter outputs these measured values as voltage, current or digital signals.

Connections and Data Transmission: The output of the sensor is transmitted to the control system or instrument panel via a data communication channel, to which it is usually connected by a cable. This communication channel is used for monitoring, recording or processing of measured pressure data.

Cable extruder pressure sensors are important for monitoring the pressure status of extruder machines, detecting manufacturing errors, ensuring product quality and optimizing process control. It provides precise and reliable measurements and helps to keep the cable manufacturing process within the desired parameters.