25

11 2020

General Operating Guidelines of Sensors

A. Avoid Cold Starts

If the extruder is not heated properly, the polymer may be in a solid state by the converter. If the extruder is started with solid state polymer, the diaphragm may rupture.

Sensor Removal

The converter should only be removed or replaced when the machine is at operating temperature and the polymer is in a liquid state.

Removing the converter from a cold extruder may cause the polymer to stick to the diaphragm; it could then pull the diaphragm or damage it. A transducer should never be installed in a mounting hole with solid polymer. If the diaphragm is forced into a solid, the transducer can easily be overloaded and left with a zero offset too high to be reset by the device's high potentiometer or severely damage the tip.

Always clean and check tip stagnation before reinstalling the transducer.

C. Tip Cleaning

If the transducer is removed from the sleeve while it is still hot, the tip can be carefully cleaned with a clean soft cloth.

D. Hole Cleaning

Mounting holes should always be cleaned before installation. Any burr or hardened polymer material can damage the diaphragm during assembly.

As the inner extruder barrel wears, it can reduce the size of the converter bore. We offer cleaning kits for 1/2 ”-20UNF and M18x1.5 converter holes. Using a cleaning kit ensures that each hole is properly sized.

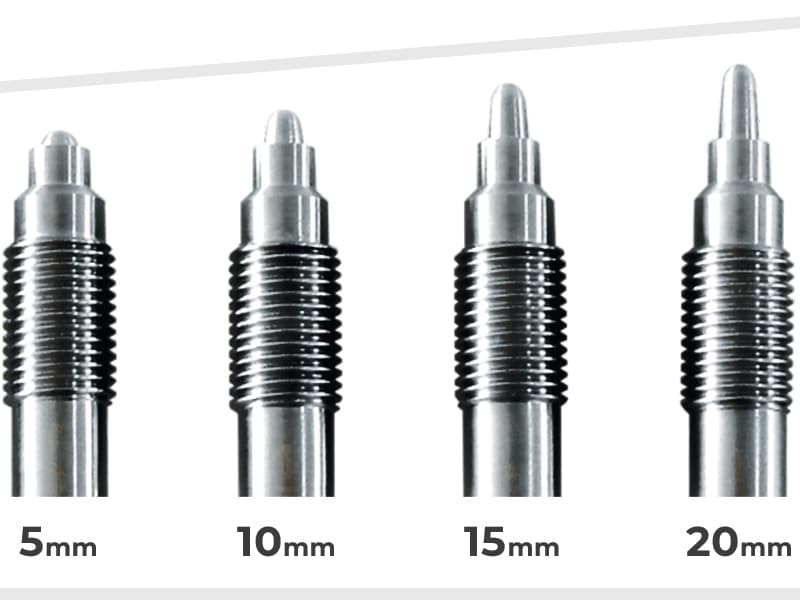

Check Hole Depth Before Replacing

As the extruder chamber wears, the converter tip will approach and approach the inner barrel wall. If the extruder is allowed to be flush with the inner barrel wall, it will wear at the same rate as the inner wall. MPS recommends maintaining a minimum of 0.02 ”stagnation. Copper shims can be made to push the tip away from the inner wall.

Keep Probes Dry

Do not allow oil or water to come into contact with the transducer or cables.